Crosby Swivel Hoist Ring Installation

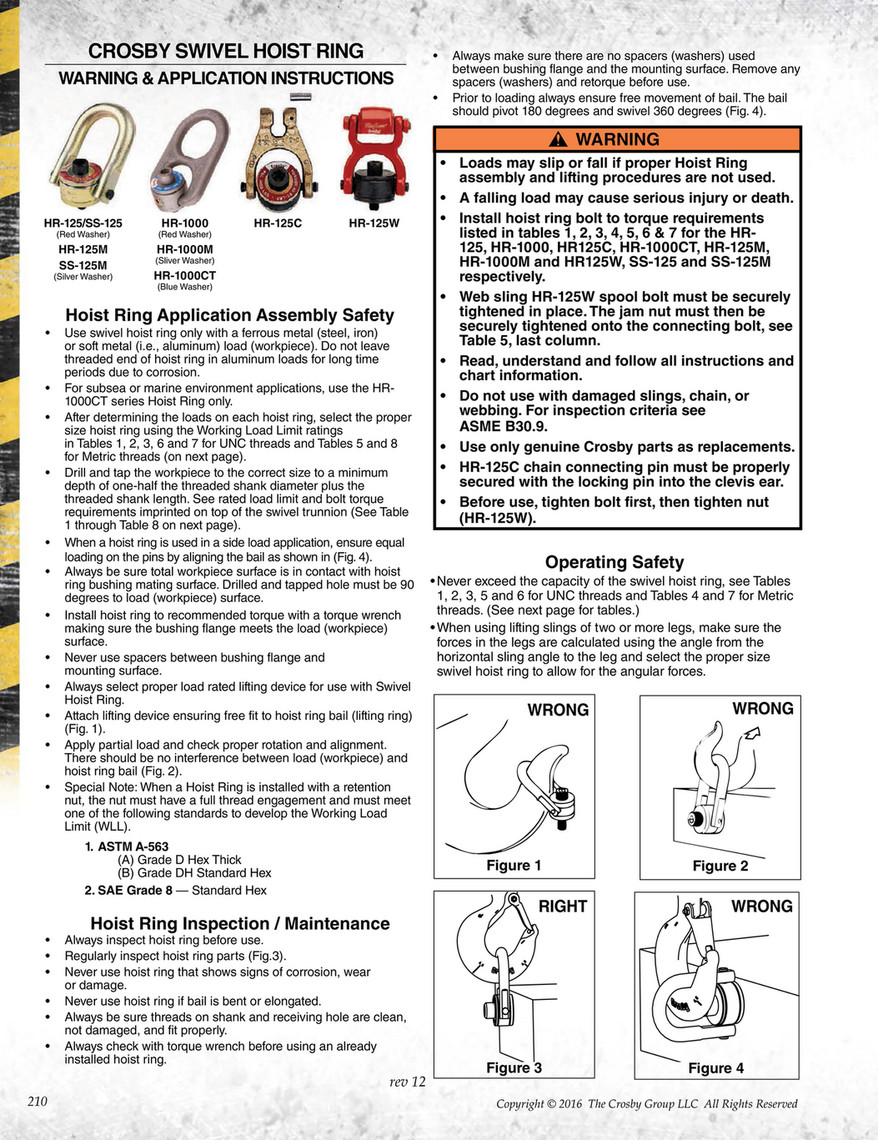

Attach lifting device ensuring free fit to hoist ring bail lifting ring fig.

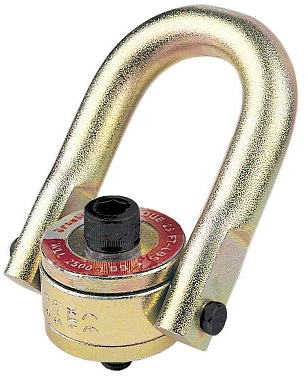

Crosby swivel hoist ring installation. The crosby brand has been trusted for more than 130 years. Crosby s full catalog and product listing of the crosby hr 125 unc swivel hoist rings. Easily readable raised lettering showing the name crosby or cg and pic code for material traceability. Always make sure the thread engagement is at least 1 5 times the diameter of the hoist ring screw.

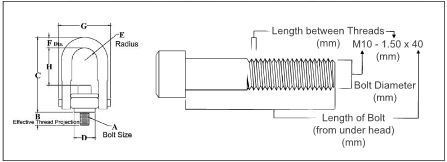

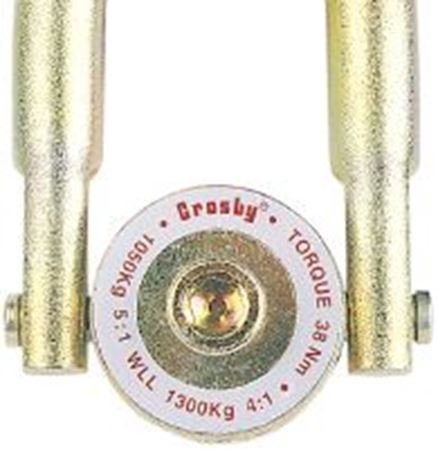

Install hoist ring to recommended torque with a torque wrench making sure the bushing flange meets the load workpiece surface. Torque wrenches are sold separately. Never use spacers between bushing flange and mounting surface. Ultimate load is 4 5 times the working load limit for 7000 hoist ring when tested in 90 degree orientation.

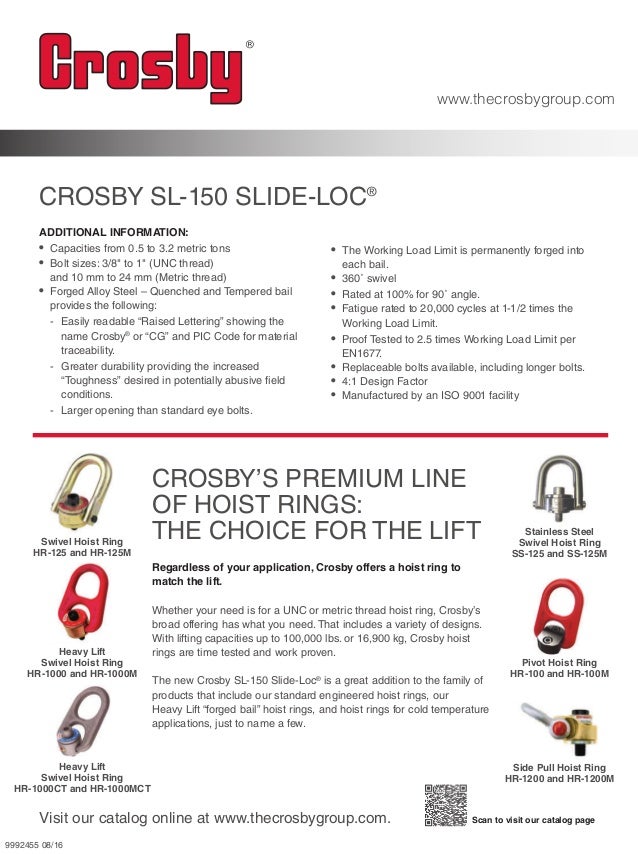

As the world s leading manufacturer for rigging lifting and material handling applications crosby delivers the industry s most comprehensive portfolio of products engineered to exceed the toughest demands. Black oxide steel offers mild corrosion resistance. Always select proper load rated lifting device for use with swivel hoist ring. Heavy lift swivel hoist rings hr 1000.

The crosby guarantee engineering and manufacturing excellence without compromise. Machined hoist rings have a smooth finish to protect slings and hooks from damage and excess wear during lifting. Install the base of the hoist ring flush to the mounting surface and tighten to the recommended torque that is stamped on the ring. Never use spacers between bushing flange and mounting surface.

Crosby hr 1000ct cold tuff unc heavy lift swivel hoist rings crosby hr 1000ct cold tuff unc heavy lift swivel hoist rings crosby hr 1000m metric heavy lift swivel hoist rings crosby hr 1000m metric heavy lift swivel hoist rings stainless steel.